Future development direction of automatic packaging line

Introduction to Automatic Packaging Lines

An automatic packaging line basically refers to a bunch of machines working together to wrap up products without anyone needing to touch them manually. The tech behind these systems has completely changed how packaging works, making things go much faster and look more consistent across batches. Back when everything had to be done by hand, packing stuff took forever and mistakes happened all the time because humans get tired and make errors. As technology improved over the years, we started seeing these fully automatic lines pop up everywhere. They just work so much better than before, saving companies money while producing packages that look exactly the same every single time.

Automatic packaging is becoming essential for manufacturers these days because it cuts down on mistakes people make and speeds things up considerably. When companies automate those boring, repetitive jobs, they get better results every time without so many quality issues popping up. Industry data shows that factories with automated systems have seen their production rates jump around 15 percent while wasting less materials overall. Most professionals working in manufacturing agree that automation isn't just helpful but actually necessary if businesses want to keep up with what customers need now and what they'll probably want next year too.

Benefits of Implementing an Automatic Packaging Line

Implementing an automatic packaging line significantly boosts efficiency and productivity by streamlining workflows and minimizing downtime. These systems automate repetitive tasks, allowing for consistent production speeds without the interruptions caused by manual processes. As a result, businesses can meet production demands more reliably and swiftly, ultimately enhancing output levels.

The numbers really speak for themselves when it comes to what automatic packaging lines can do for efficiency. Research shows that factories implementing these systems often see their production rates jump by around 30%, and some report cutting labor costs by about 15%. These improvements mean more than just faster output though. Companies find they can redeploy their workforce smarter ways. Instead of repetitive packing tasks, experienced staff members get to handle quality control checks or troubleshoot equipment issues where their expertise actually makes a difference in both product quality and overall business performance.

Automatic packaging lines help cut costs and reduce waste because they're so precise with how much material gets used. The engineering behind these systems makes sure there's no overuse of packaging materials, which means less goes to landfill sites. For manufacturers, this careful approach saves real money on their bottom line. Beyond just saving cash though, companies are starting to see automated solutions as smart choices for the planet too. Many business owners now factor sustainability into their equipment decisions alongside traditional cost considerations.

Industries that have successfully implemented these systems demonstrate the transformative benefits. Take the food sector, for instance: they often follow a structured implementation process, such as:

- Conducting a needs assessment.

- Designing a system layout.

- Installing the equipment.

- Providing staff training.

This systematic approach ensures a seamless transition to automated lines, fostering growth and enhanced sustainability.

Key Components of an Automatic Packaging Line

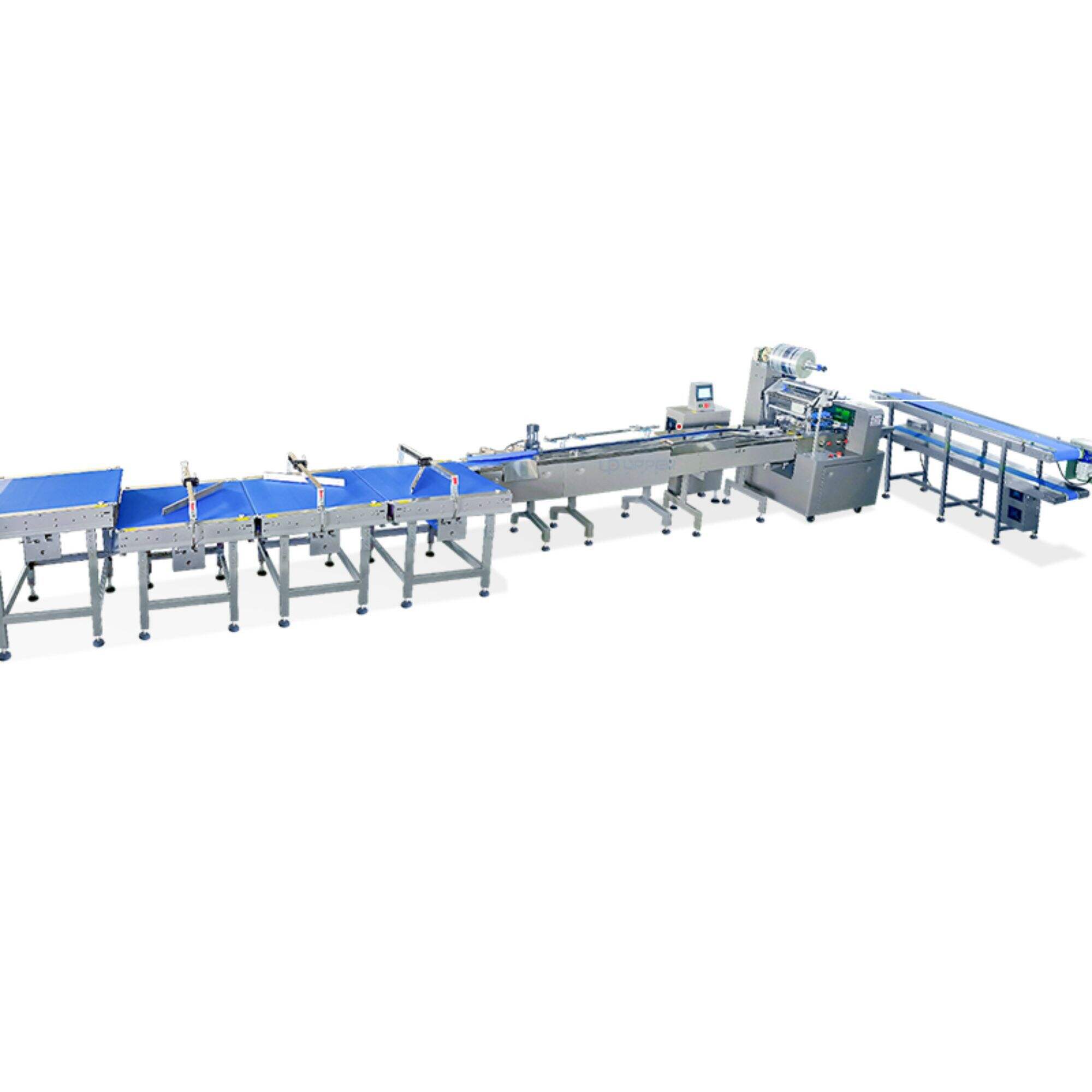

Automatic packaging lines consist of multiple essential parts working together to speed things along in the packaging world. Conveyor belts play a big role here since they keep products moving smoothly through different stages of packaging without needing workers to constantly handle them. Products just glide from one part of the process to another thanks to these conveyor setups. Some systems run straight across while others bend around corners based on how the factory is laid out and what exactly needs to get done. When designing these conveyor networks, manufacturers think about both what kind of goods are going through and how much space they have available in their facilities. After all, nobody wants their precious cargo getting stuck somewhere because there wasn't enough room for proper movement.

Automatic feeders play a key role in keeping products moving smoothly into packaging machines without interruption. These systems come in all sorts of configurations depending on what kind of packaging job needs doing. Take those high precision models with servo motor control for example they work great when accuracy matters most. Then there are simple conveyor based systems that handle the basics just fine for straightforward applications where fancy features aren't necessary. What really matters is how these feeders keep things running non stop throughout the packaging line. When properly set up, they prevent those annoying slowdowns caused by empty pockets between batches, which everyone knows can bring production to a grinding halt if left unchecked.

Sealing and labeling equipment is really important for keeping products safe and following all those labeling rules that manufacturers have to遵守. The sealing part basically locks down packaging so nothing gets into it or goes bad during transport or storage. Labeling machines slap on all the necessary info like company logos, what's inside, expiration dates, and all sorts of regulatory stuff that governments require. Most factories need these systems just to stay compliant with food safety laws or pharmaceutical standards. While pictures would definitely help explain how everything connects together in a production line, we don't have visuals here. Still, anyone who works on packaging lines knows firsthand how much difference proper sealing and accurate labeling makes when products hit store shelves.

Industry Applications of Automatic Packaging Lines

Packaging lines that operate automatically are now essential across the food sector, helping companies stick to strict safety rules and keep things clean. These systems handle tasks like filling containers, sealing them tight, and applying labels, which cuts down on the chance of contamination from all sorts of sources. Beyond just keeping food safe to eat, they actually help preserve taste and texture longer too. For instance, many snack manufacturers report their products stay fresh weeks longer when packaged this way compared to traditional methods.

For pharma companies, getting packaging right matters a lot. Automated systems bring both precision and dependability to the table. Drug manufacturing faces all sorts of rules and regulations these days. That's why many firms turn to automated packaging lines which get dosing amounts spot on and seal containers properly every time. This cuts down mistakes made by people working on assembly lines and keeps everything within legal boundaries set by health authorities. Plus, modern automation makes it easier to track products thanks to detailed labels showing batch numbers and expiration dates something regulators really care about in this highly controlled industry.

Automated packaging makes a real difference in the cosmetics and personal care sector. Packaging lines handle all sorts of fancy designs and brand elements that make products stand out when they hit store shelves. With automation comes the ability to personalize packages and incorporate brand identity, something that matters a lot when trying to grab attention in today's crowded marketplace. Products look better on display, sure, but there's another benefit too consistent quality between different production runs. No matter how many units come off the line, each one maintains that same level of finish and presentation.

Industry data shows just how much automation affects production speed and overall efficiency in manufacturing settings. Take packaging operations for example many businesses have seen their output jump around 25% after switching to automated systems instead of relying solely on manual labor. The difference is pretty dramatic when comparing old school methods with what modern tech can deliver. Beyond boosting productivity, automated setups also cut down on expenses because they require fewer workers while making mistakes almost nonexistent. Food processing plants, automotive assembly lines, and pharmaceutical manufacturing facilities all benefit greatly from these kinds of improvements, which explains why so many companies are investing heavily in automation despite the initial costs involved.

Exploring Innovations in Automatic Packaging

The latest developments in automated packaging are changing how people interact with products thanks to clever tech additions. Packaging now comes equipped with things like QR codes and various sensors that make products more interactive. Consumers can scan these codes to get instant info on where something came from, how to use it properly, and sometimes even check if it's still fresh. For companies, this means better ways to connect with customers while building trust. When shoppers can see exactly what they're getting and access extra services right from the box or container, brands look more reliable and honest about their offerings.

Smart features really make a difference when it comes to tracking products and keeping them safe during transport. When companies install sensors into their goods, they get real time updates on temperature changes, humidity levels, and whether packages remain intact as they move through warehouses and delivery trucks. This helps cut down on losses caused by broken items or spoiled perishables. Industry experts point out that these tech solutions have completely changed how we track products nowadays. The systems can send instant alerts if something goes wrong anywhere along the journey, so problems get fixed before they become major issues. What this means is better quality control all the way from factory floor to customer doorstep.

Green initiatives have become central to how packaging automation is developing these days. A growing number of businesses are switching to environmentally friendly materials and methods that meet today's green requirements. When manufacturers start using biodegradable stuff for their packages and work on making their production lines generate less trash, they're actually cutting down on the environmental impact of their whole operation. Big names in the industry, including Coca-Cola and Nestle, have made moves toward sustainability already. Their efforts have led to real decreases in both waste generated and resources used up, which proves just how beneficial going green can be for automated packaging systems.

Case Studies of Automatic Packaging Lines

Automatic packaging lines have proven to be revolutionary in diverse manufacturing sectors, enhancing efficiency and ensuring consistent quality. Let's explore three notable examples to draw insights into their implementation and benefits.

Mochi Automatic Packaging Line

Upper's Mochi Automatic Packaging Line stands out as something really special in the world of automated packaging solutions. What makes it stand apart? Well, it comes equipped with a dual frequency conversion control system that keeps things running smoothly and quietly most of the time. Operators love working with the Human Machine Interface (HMI) because adjusting parameters becomes second nature after just a few sessions. Getting those sealing points right and making sure cuts land exactly where they should isn't rocket science anymore thanks to this setup. Factories that have installed these lines report noticeable improvements in their day to day operations. Production numbers go up while product quality stays consistent across batches. And let's not forget about what happens to labor costs when repetitive tasks get handled automatically instead of requiring constant human oversight throughout shifts.

Croissant Bread Automatic Packaging Line

Built for large scale operations, the automatic packaging line for croissants handles complicated production requirements without breaking a sweat. The system brings together several key functions like sorting materials and diverting products when needed, making the whole packaging operation run smoother. What really stands out is how well it bags and seals each individual croissant, something that makes a real difference in how long they stay fresh on store shelves. There's also a special rack built into the machine where preservatives get added during the process, keeping those delicate pastries tasting good for longer periods. For bakeries dealing with big orders or running multiple shifts, this kind of automation cuts down on mistakes made by people and gets products wrapped up much faster than manual methods ever could.

Cup Cake Fully Automatic Packaging Line

The Cup Cake Fully Automatic Packaging Line was built specifically to tackle those tricky production challenges manufacturers face daily when dealing with sorting, feeding, and actually getting cupcakes into packages without messing them up. What really sets this system apart is how it arranges each cupcake just right before sealing them off, which means no two batches look different from one another in terms of presentation or quality standards. Made entirely from food grade stainless steel components that meet all safety regulations, these machines are designed so cleaning between runs takes minutes instead of hours while still maintaining top performance levels throughout long shifts. For bakeries running multiple production lines at once, this equipment handles massive quantities effortlessly compared to older systems, saving both time and money on labor costs while keeping up with customer demand fluctuations across seasons.

Cross-Comparison and Insights

Looking at real world implementations shows what works well and where problems tend to pop up with automatic packaging systems. The successful ones usually have good safety built in from day one, reduce how much people need to touch things during operation, and are flexible enough to work with different kinds of products without losing speed. On the flip side, getting started often hits roadblocks because of the money needed upfront, the physical footprint required, and just how complicated some of these systems actually are. Small businesses especially struggle with this stuff. When companies take time to really understand all these aspects before jumping in, they stand a better chance of making smart investments that pay off long term rather than ending up stuck with expensive headaches down the line.

Conclusion

Looking ahead, automated packaging stands on the brink of major transformations fueled by growing interest in automation and smart tech. Many manufacturers are already jumping on board with AI powered systems that make their packaging lines faster and much more accurate than traditional methods. The real game changer comes from how these smart technologies can cut waste while speeding up production cycles. Food processing plants and pharmaceutical companies especially benefit from this shift toward smarter packaging solutions. What we're seeing now is just the beginning what could become standard practice within five years as costs continue to drop and capabilities expand.

EN

EN

AR

AR

FR

FR

PT

PT

RU

RU

ES

ES

ID

ID

TH

TH

KO

KO

JA

JA

VI

VI

NL

NL

IT

IT

DE

DE