Intelligent Customization, Flexible Future: The Transformation of Automated Food Packaging Lines

Intelligent Customization, Flexible Future: The Transformation of Automated Food Packaging Lines

Where standardization fades, Upper's non-standard solutions are writing the future of food packaging.

Robotic arms delicately lift artisanal chocolates into custom-molded packaging; real-time data flows across screens predicting maintenance needs three hours ahead. Driven by digitalization and sustainability, the food packaging equipment industry is undergoing an intelligent revolution—and Upper’s latest innovations are leading the charge.

01 Smart Flexible Production: Redefining Packaging Paradigms

New Solution: Triple Centrifuge Chocolate Packaging Line

· Revolutionary Design: Three centrifugal turntables with synchronized vision inspection enable high-speed counting and sorting of irregular chocolates

· Intelligent Handling: Spider robots perform secondary packaging with 0.1mm precision

· Custom Advantage: Adjustable force control prevents damage to delicate products

Perfect for premium chocolate brands requiring gentle handling of artisan shapes

Key Flexibility Features:

· Vision-guided AI systems automatically adapt to product variations

· Modular design allows reconfiguration for new formats in under 30 minutes

02 Green Tech Revolution: Sustainable Packaging Solutions

New Solution: Rice Cake Automatic Tray Loading System

· Universal Compatibility: Processes various tray-based products (cakes, mooncakes, cookies)

· Eco-Smart Design: 30% material reduction through optimized tray forming

· Energy Efficiency: Servo-driven mechanisms cut power consumption by 25%

Eliminates manual handling for fragile baked goods while reducing waste

Sustainability Breakthroughs:

· Precision dosing reduces product giveaway by 3-5%

· Self-adjusting molds accommodate recycled material variations

03 Data-Driven Customization: Solving Complex Challenges

New Solution: Black Coffee Automatic Boxing Line

· Smart Sorting: Centrifugal disc with AI vision identifies and orients diverse products (sticks, sachets, pouches)

Multi-Format Mastery: Seamlessly handles solids, powders, and filter bags

· Data Integration: OEE tracking with real-time production analytics

Processes 120+ items/minute with 99.98% accuracy

Non-Standard Capability Spotlight:

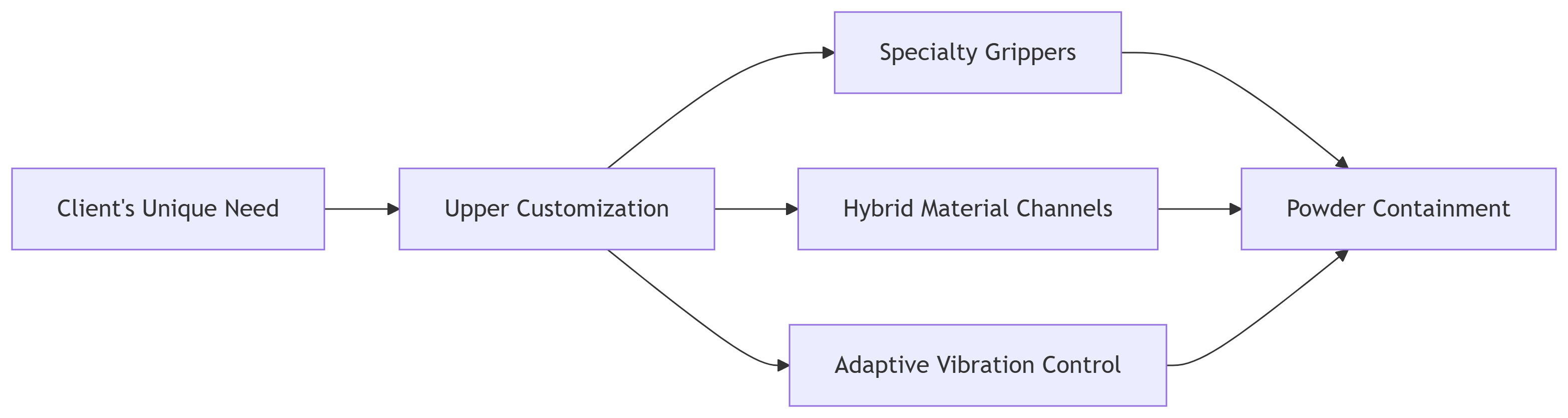

04 Customized Non-Standard Solutions: Engineering Excellence

Why Off-the-Shelf Fails:

Standard machines struggle with:

· Mixed batches of irregular coffee sticks

· Delicate chocolate transfer without surface marks

· Variable-thickness rice cake loading

Upper's Custom Advantage:

· Material Science Expertise: Food-grade anti-stick coatings

· Motion Control Innovation: G-force regulated centrifugal systems

· Rapid Prototyping: 50% faster solution development than industry average

05 Future-Ready Integration

New Generation Synergies:

· Chocolate line’s vision system predicts maintenance needs

· Coffee boxing line integrates with ERP for batch traceability

· All systems feature plug-and-play IoT connectivity

Non-Standard Impact:

“Upper’s chocolate line cut our premium product damage rate from 5.2% to 0.3% while doubling output.”

– European Confectionery Manufacturer

Why Customers Choose Upper’s Custom Approach:

|

Challenge |

Standard Solution |

Upper Customized |

|

Irregular shapes |

High rejection rate |

Triple centrifuge precision orientation |

|

Fragile products |

Manual handling |

Adaptive force control automation |

|

Mixed formats |

Multiple machines |

Single-line multifunction processing |

Tomorrow’s factory floor features Upper’s flexible lines silently switching between packaging formats. Custom non-standard solutions aren’t optional—they’re strategic imperatives for winning in food manufacturing.

Discover how Upper’s new generation systems can transform your production:

➤ Chocolate Line: 45% faster changeovers for limited editions

➤ Rice Cake System: 90% reduction in manual handling

➤ Coffee Packaging: 30% higher density palletizing

Behind every production challenge lies a solution waiting to be engineered.

EN

EN

AR

AR

FR

FR

PT

PT

RU

RU

ES

ES

ID

ID

TH

TH

KO

KO

JA

JA

VI

VI

NL

NL

IT

IT

DE

DE