Application scenario expansion of automatic packaging line

Introduction to Automatic Packaging Lines

Automatic packaging lines represent complete systems that take over product packaging tasks using machinery and tech innovations. They handle everything from filling containers to sealing packages, adding labels, and wrapping items - jobs that used to require manual labor across multiple workstations. The push toward automation in packaging comes down to simple math for manufacturers: faster production means meeting customer demands without breaking budgets. When factories install these automated setups, they see real improvements in their output numbers while cutting down mistakes made by human workers. Consistent quality becomes standard rather than lucky accident, something that matters a lot when competing against other brands in crowded markets. Companies investing in this kind of equipment often find their staff members get reassigned to roles requiring problem solving skills instead of repetitive motions all day long.

Versatile Applications of Automatic Packaging Lines

Automatic packaging lines have become essential across many manufacturing sectors because they can handle different tasks quickly and reliably. The food processing world relies heavily on these automated systems for everything from snack bars to frozen meals and carbonated drinks. What makes them so valuable isn't just speed though. These machines maintain strict hygiene protocols during operation, something absolutely necessary when dealing with consumable goods. Without proper sanitation controls built into the machinery, there would be serious risks of bacterial growth and product spoilage before items even reach store shelves.

Automatic packaging lines play a vital role in both pharmaceutical and cosmetic industries where accuracy matters most under strict regulatory requirements. The machines make sure meds and skincare items get wrapped properly so they stay safe and effective until they reach consumers' hands. Mistakes here aren't just inconvenient they can actually put people at risk. Think about it wrong dosage labels on pills or contaminated makeup containers those kinds of issues happen when packaging isn't done right. That's why manufacturers invest heavily in these systems despite the costs involved.

The electronics business isn't the only one getting value out of automatic packaging systems. Many other industries have found these machines incredibly useful too. They can handle all sorts of products, including things like smartphones, circuit boards, and even small mechanical components. What makes these systems stand out is how they can work with products of completely different shapes and sizes without missing a beat. For manufacturers dealing with changing product mixes, this kind of flexibility saves time and money. Factories that switched to automated packaging report better output rates and fewer errors in their packaging processes. The bottom line is that when companies need reliable packaging solutions that keep up with production demands, automatic lines tend to be the go to option these days.

Key Components of An Automatic Packaging Line

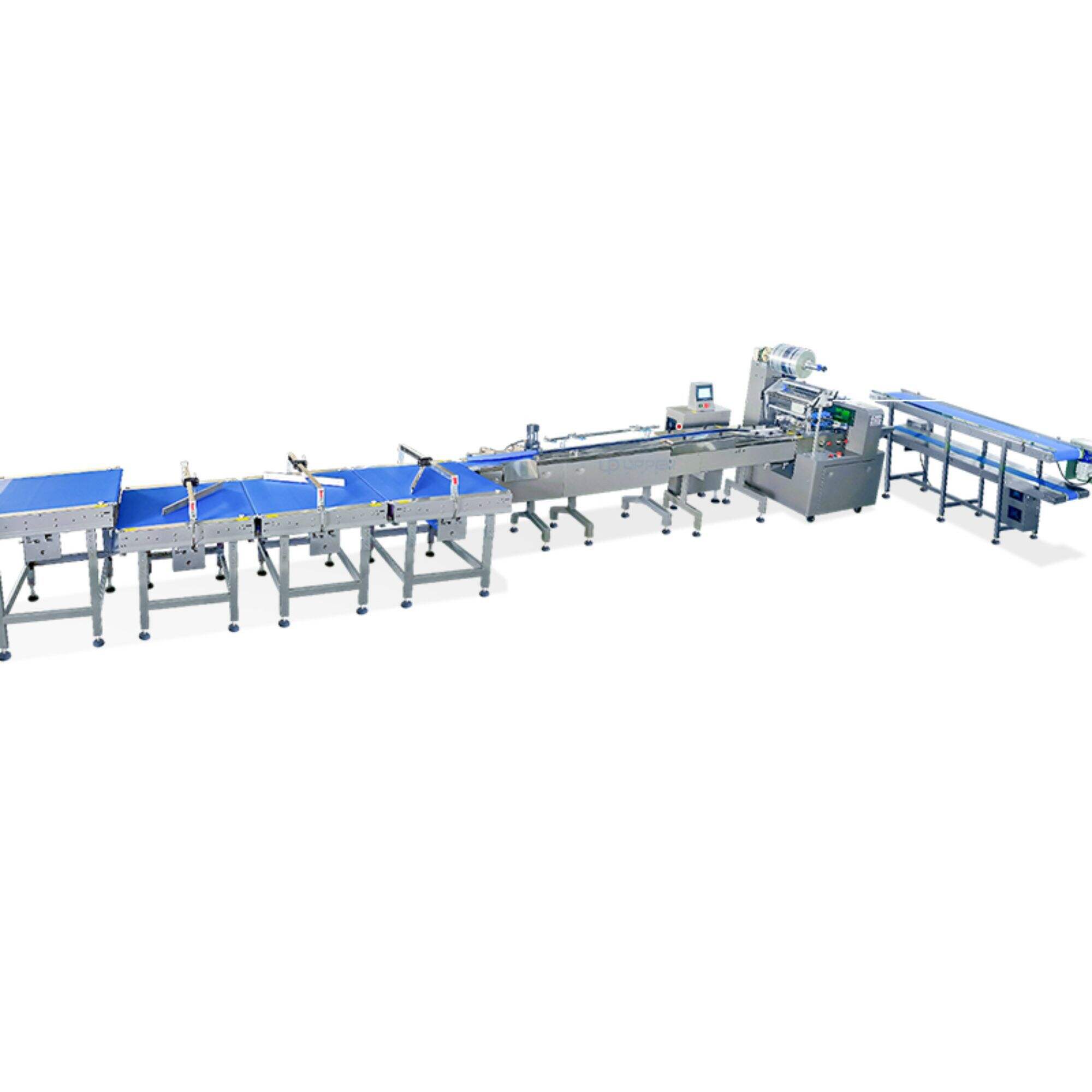

At the heart of any automatic packaging system lies components that really boost how fast things get done and overall productivity levels. When it comes to getting products from point A to B along the line, transfer mechanisms just cant be ignored. Manufacturers rely on all sorts of tech here including standard conveyor belts, those fancy robotic arms we see everywhere these days, plus simple roller systems too. Conveyors remain popular choice because they dont break the bank and work great whether going straight ahead or around corners. Meanwhile robotic arms offer something different altogether they can pick up almost anything regardless of shape or size, which makes them super valuable when dealing with irregular items that regular equipment might struggle with.

Automatic feeding systems form another key component in automated packaging lines, making sure products get loaded properly onto the machinery. There are several different kinds out there, including bulk feeders and hopper systems, each built for handling specific product shapes and sizes. The bulk feeders work great when dealing with lots of items at once, moving them along without much trouble. Hopper systems take care of those smaller pieces though, arranging everything neatly before sending them down the line. These setups help keep operations running smoothly most of the time, cutting back on the need for manual labor throughout the process.

Sealing and labeling tech plays a big role in keeping products safe while meeting all those labeling rules companies have to follow. Heat sealing works great for most applications, creating tight seals that stop anyone from messing with the contents or letting moisture in. Cold sealing is another option when things need to be sealed quickly without generating heat. When it comes to labels, modern systems make sure everything gets properly tracked from factory floor to customer hands. Compliance isn't just paperwork either these days good labeling actually makes the whole packaging line run smoother too. Many manufacturers find that investing in better sealing and labeling solutions pays off in both safety improvements and operational efficiencies down the road.

Benefits of Using an Automatic Packaging Line

Putting in place an automated packaging system really ramps up how much gets done in manufacturing settings. Studies show that machines can pack products about six times faster than people working manually. Less reliance on hands-on labor means things move quicker overall, plus there's less stoppage when mistakes happen or workers get tired. The whole process just keeps rolling along without those annoying hiccups that slow down production so much.

Moreover, automatic packaging lines contribute to cost reduction and labor reallocation. Though the initial investment might seem substantial, companies eventually save on labor costs as automated systems take over repetitive tasks. This shift allows businesses to redeploy employees to higher-value roles, improving overall resource allocation and productivity.

Furthermore, automation enhances product quality and consistency. Automated systems ensure standardized packaging processes, reducing the likelihood of product damage during packing. By maintaining uniformity across batches, businesses enhance their reputation for reliable quality, which in turn can lead to increased customer satisfaction and loyalty.

Product Showcase: Automatic Packaging Solutions

Mochi Automatic Packaging Line

The Mochi Automatic Packaging Line offers something special for those dealing with mochi and other soft goods that break so easily. What makes this system stand out? Well, it comes with moisture control features and handles products gently throughout the whole process. This helps keep that wonderful texture intact while maintaining all the original flavors people love in their mochi snacks. Behind the scenes, there are these really advanced sensors working hard to position materials just right every single time. The result? Less wasted product and faster production speeds across the board. Operators will appreciate the intuitive controls on the machine too. They can tweak settings quickly when needed without standing around waiting for things to happen manually all day long.

Croissant Bread Automatic Packaging Line

The Croissant Bread Automatic Packaging Line is basically a well thought out system that keeps those flaky croissant layers intact without slowing down the whole packaging process. What makes this machine stand out? Well, there's this special desiccant dispenser built right in that helps keep the pastries fresh longer after they leave the oven. And let's talk about the automation part because that's pretty impressive too. The machine handles sorting and bagging all on its own, so every single croissant gets wrapped up properly without any inconsistencies. Built for serious volume work, this line isn't limited to just croissants either. Bakeries can switch things up pretty easily between different products, which means one investment covers multiple production runs throughout the week.

Cup Cake Fully Automatic Packaging Line

The Cup Cake Fully Automatic Packaging Line brings together smart engineering and modern tech to pack cupcakes without causing any damage during the process. Designed for speed but still keeps those pretty presentation aspects intact when wrapping products. Automated systems take care of feeding items into place, stack them properly, then arrange bags around each batch. What really matters here though is how consistently it produces quality results every time. For companies trying to stand out in tough markets where looks count just as much as taste, having reliable packaging that doesn't compromise appearance becomes absolutely critical to their success.

Challenges and Limitations of Automatic Packaging Lines

Getting automatic packaging lines up and running means spending a good chunk of money upfront, something that keeps不少 businesses from making the switch. The cost is way higher than what traditional methods demand, especially for small operations working with tight budgets. Companies looking at this transition face expenses beyond just buying the machines themselves. Installation fees, employee training sessions, and sometimes even overhauling entire production areas all add to the bottom line. Most manufacturers find they have to look years ahead when calculating if these investments pay off. Enhanced efficiency in the long run helps offset those initial expenses, as does cutting down on manual labor costs over time. But getting there requires careful planning and realistic expectations about when returns will start coming in.

Automatic packaging lines bring their own set of challenges when it comes to keeping them running smoothly. The machines themselves are pretty complicated beasts that react strongly to even small changes in how they're operated. When something goes wrong, fixing these issues often requires someone who really understands the inner workings of the equipment. A breakdown in production line can mean hours or even days lost while repairs happen, so most facilities end up scheduling routine checks and sometimes pay for those expensive service contracts just to be safe. Some companies find themselves stuck between wanting reliable operation and controlling costs associated with all this maintenance work.

Running automatic packaging systems really needs people with know-how. Operators need proper training just to keep things running smoothly and fix problems when they come up. Most automated packaging setups involve pretty sophisticated tech这些东西, so companies either have to spend money on training existing staff or bring in folks who already know what they're doing with this kind of machinery. And let's face it this reliance on skilled workers can drive up payroll expenses quite a bit. It also creates headaches for manufacturers located in regions where finding qualified technicians is becoming harder day by day.

Conclusion: The Future of Automatic Packaging

Automatic packaging looks set to undergo some pretty big changes in the coming years, driven by things like internet-connected devices, AI systems, and smarter packaging materials. What we're seeing now are these high tech fixes that could completely change the game for packaging operations across factories everywhere. Take those machines connected to the internet of things for example they let operators keep an eye on everything happening right then and there, which means fewer breakdowns and saving money over time. Some companies have already started implementing these systems and reported getting their maintenance schedules down by almost half in some cases.

Looking at the bigger picture, companies that invest in automated packaging equipment tend to gain significant benefits over time which really affects their ability to compete effectively. These machines boost production rates while maintaining uniform product quality across batches, something that builds brand reputation in the marketplace. With ongoing advancements in tech, manufacturers who adopt these automated processes generally see better efficiency metrics and higher standards of finished goods. This puts them ahead of competitors struggling with manual operations in markets where differentiation matters most. Many food processors and pharmaceutical firms already report up to 30% cost savings after switching to fully automated lines.

EN

EN

AR

AR

FR

FR

PT

PT

RU

RU

ES

ES

ID

ID

TH

TH

KO

KO

JA

JA

VI

VI

NL

NL

IT

IT

DE

DE