Our UPPER Case Packaging System is not just any ordinary packing system; it offers high-speed operation that significantly increases throughput, allowing businesses to keep up with their production schedules and meet the growing demands of the market.

Make your packing process easier with UPPER’s easy-to-use scenario-based case packaging systems. We have designed them in such a way that any operator can learn it fast, thereby cutting down on training time and reducing errors made during operation. The controls are transparent and the interface is intuitive so as to enable you achieve professional-looking packages consistently using our case packer every single time irrespective of your experience level in this field.

Use the energy-saving case packaging systems by UPPER in order to cut down on your electricity usage and operating costs. We have developed our systems to be efficient – they use less power but still perform well. With these systems, you are not only going to make more money but also help save our environment for tomorrow by contributing towards sustainability at large.

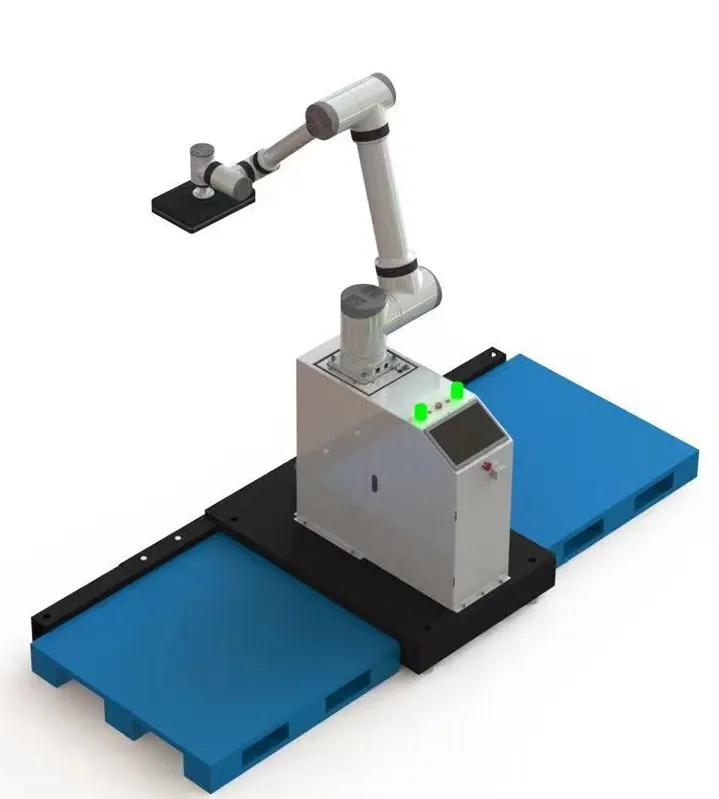

Customizable to fit your individual packaging requirements, case packing systems from UPPER provide a variety of options for modification. Our systems can be transformed into different product sizes and shapes by adjusting their speed or using modular design. Such kinds of packing machines are therefore most suitable for enterprises that want to respond flexibly to shifts in demand patterns because they enable one pack various things at different times.

Designed to be used continuously without breaking down, the case packaging systems of UPPER are created with toughness as their primary feature. These machines have been built solidly and use only top notch materials; hence they can handle extremely heavy loads comfortably. You can depend on our case packagers to keep your packaging line working well even if the conditions are severe or challenging.

Foshan Upper Machinery Equipment Co., Ltd. was founded in2011. It is an innovative automated packaging equipment manufacturer integrating R&D, design, manufacturing, sales and after-sales. Since its establishment more than ten years ago, the company has attracted a group of more than 80 professionals who are persistently pursuing the mechanical industry. The number of talents who have grown up with the company has reached 12, and they have designed and manufactured automatic packaging equipment with leading technology in China and oversea.

The company specializes in manufacturing: automatic product flow packaging line, pillow packaging machine, food packaging machine, daily chemical products packaging machine, hardware accessories packaging machine, pouch dispenser, secondary packaging machine, automatic carton packing filling machine, bag sorting machine, customized counting collection machine, customized processing line packaging equipment.

Our UPPER automatic packaging lines are designed to maximize efficiency, reducing packaging times by up to 50% compared to traditional methods. This rapid throughput ensures your products get to market faster, giving you a competitive edge.

With UPPER, precision is paramount. Our automatic packaging lines ensure each product is wrapped and sealed with exacting standards, minimizing waste and guaranteeing a professional presentation that enhances your brand's reputation.

Invest in UPPER for long-term savings. Our automatic packaging lines significantly reduce labor costs and material waste, offering a cost-effective solution that optimizes your packaging budget without compromising on quality.

UPPER offers a variety of case packaging systems designed for different industries and applications. These may include automatic, semi-automatic, and custom-designed systems to meet specific packaging needs.

Yes, UPPER case packaging systems are versatile and can accommodate a wide range of product sizes and shapes. They often feature adjustable mechanisms to ensure proper packaging for different items.

Regular maintenance is essential to keep case packaging systems running smoothly. This typically involves routine inspections, cleaning, and replacing worn parts as needed.