play dough Multi channel sorting collect feeding and packaging line Equipped with Large size tray less pillow packaging machine

Product Description

Product Description

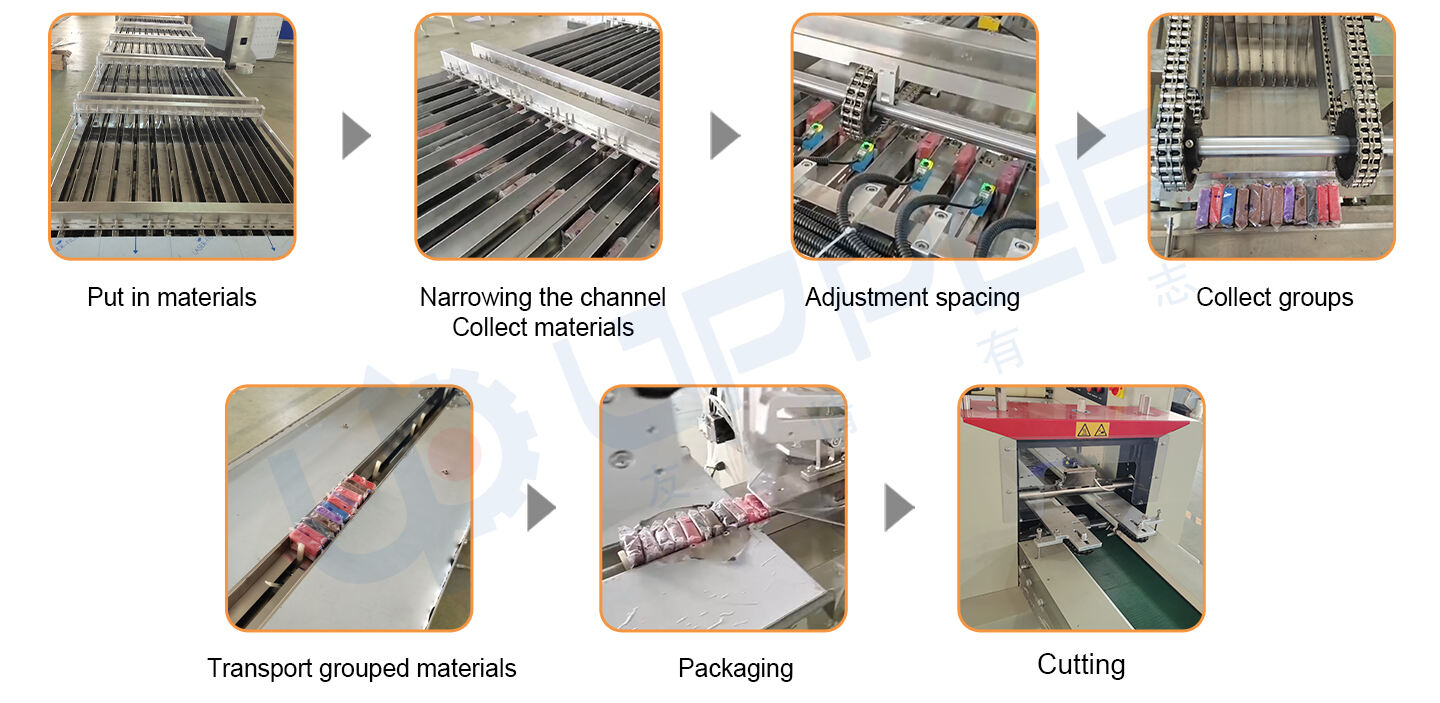

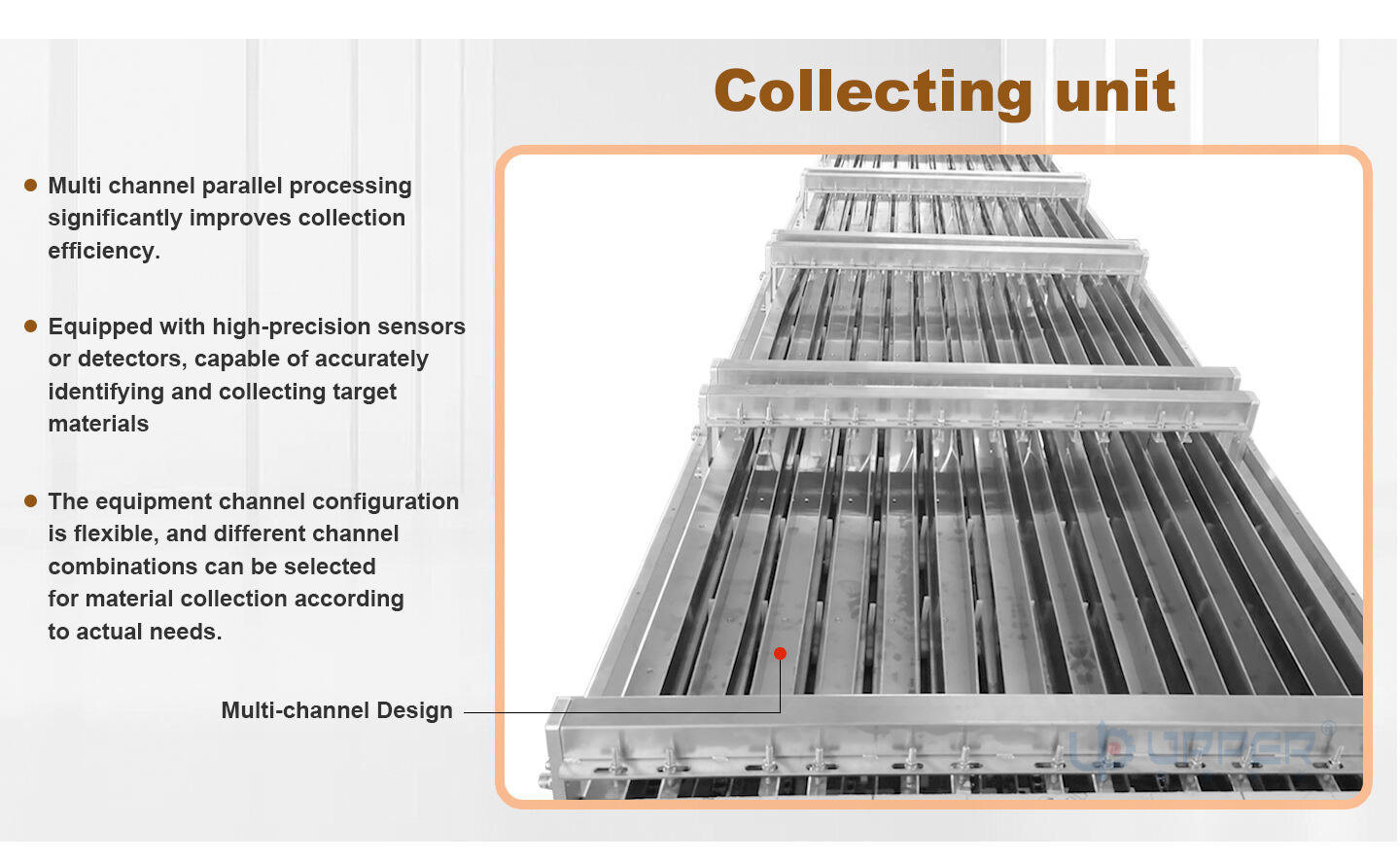

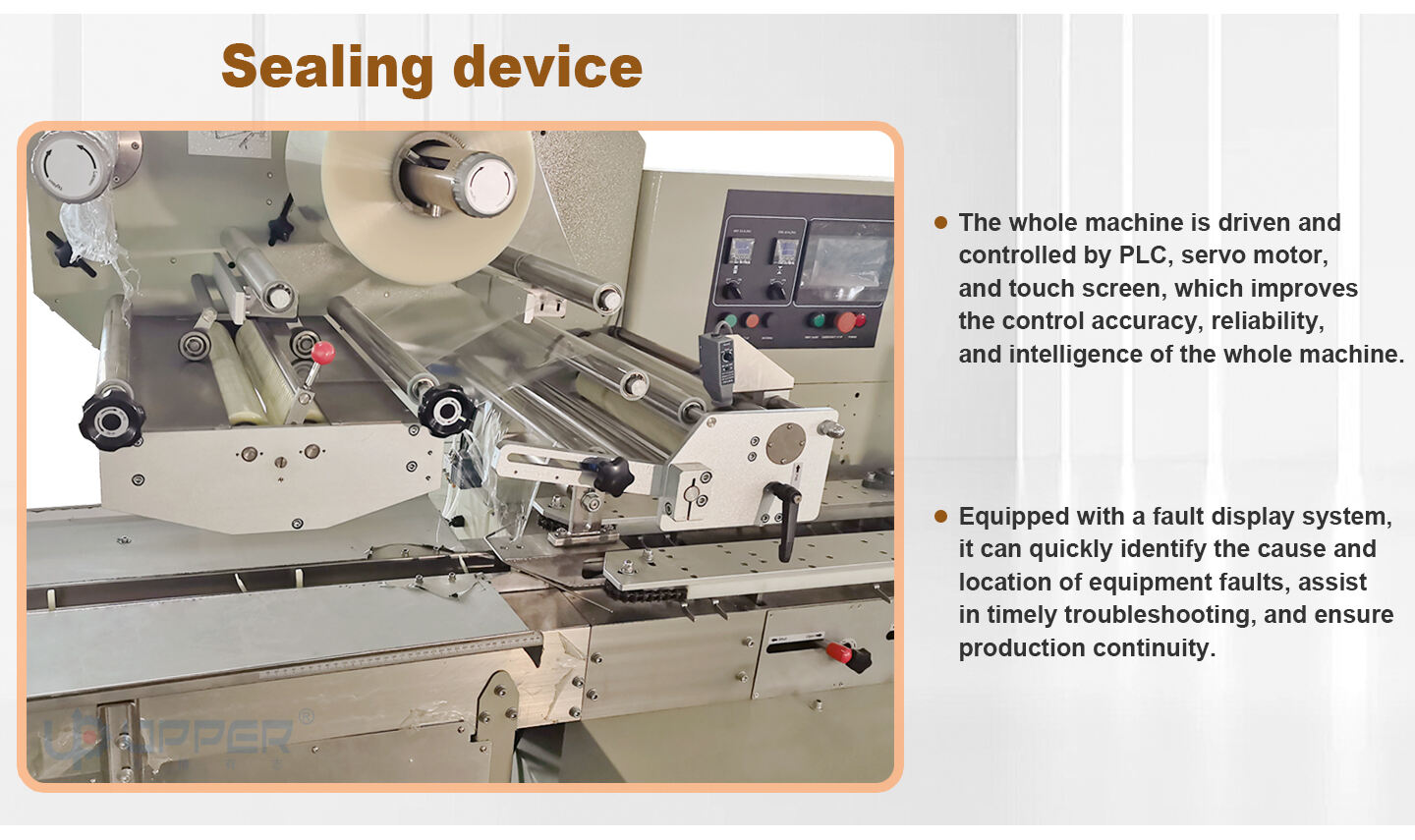

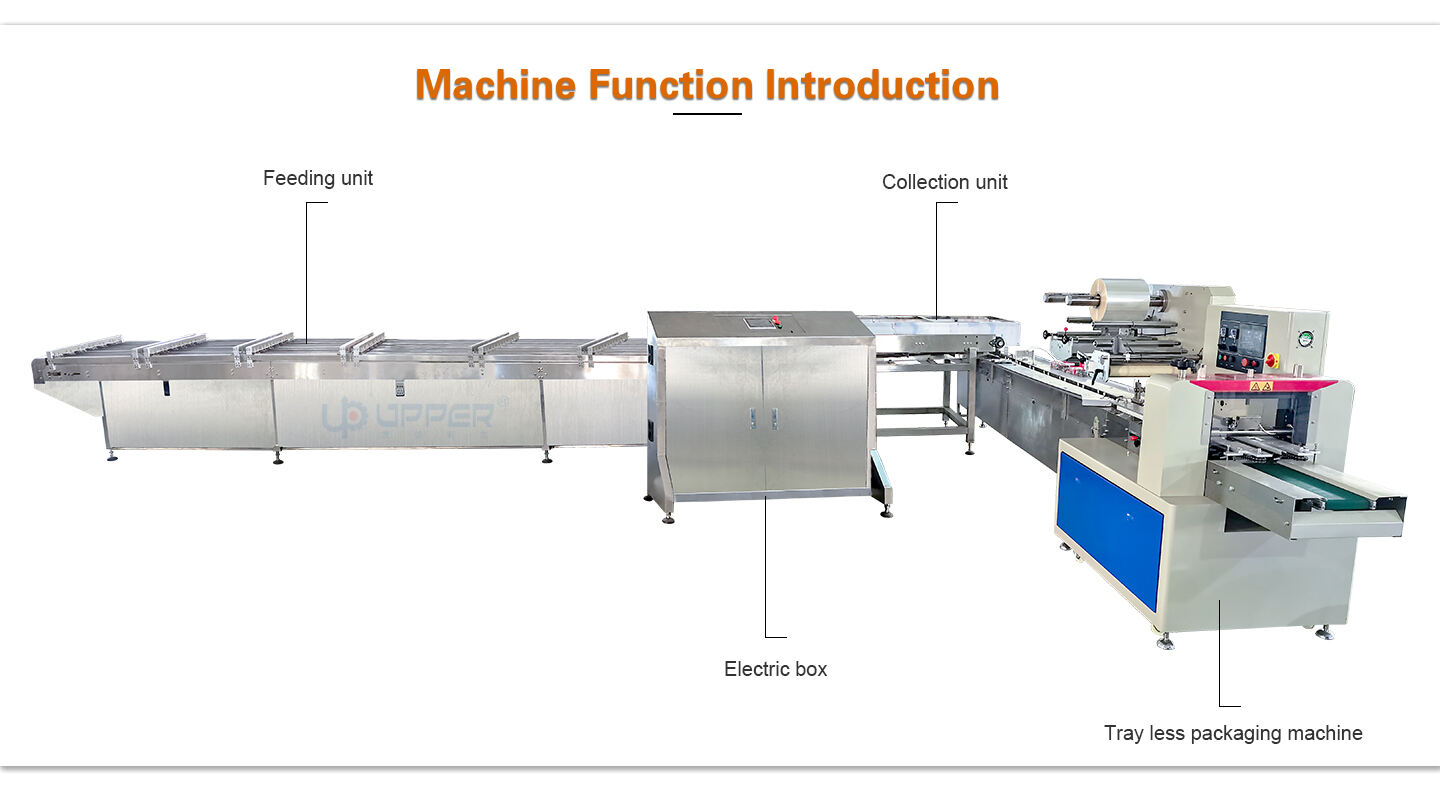

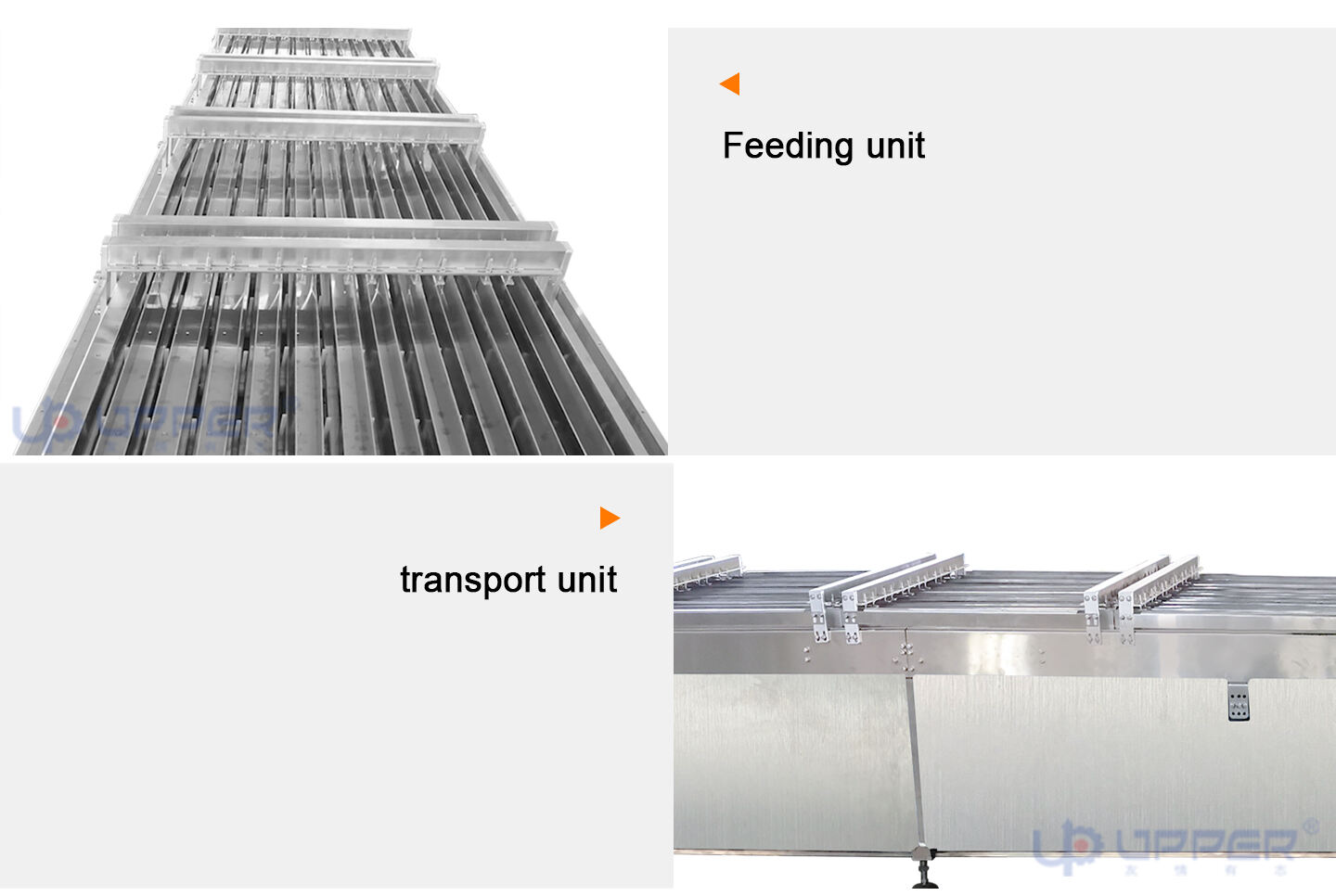

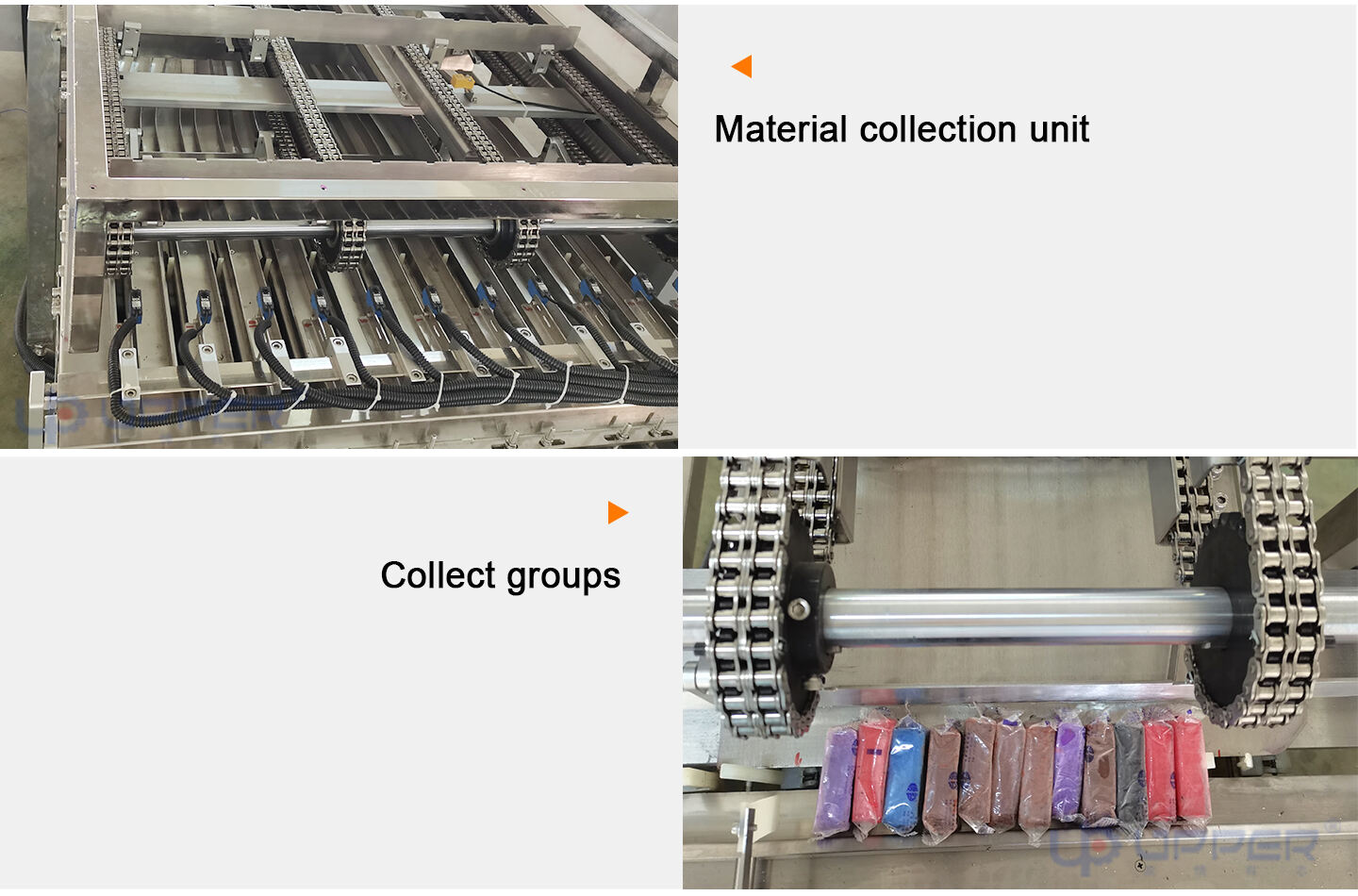

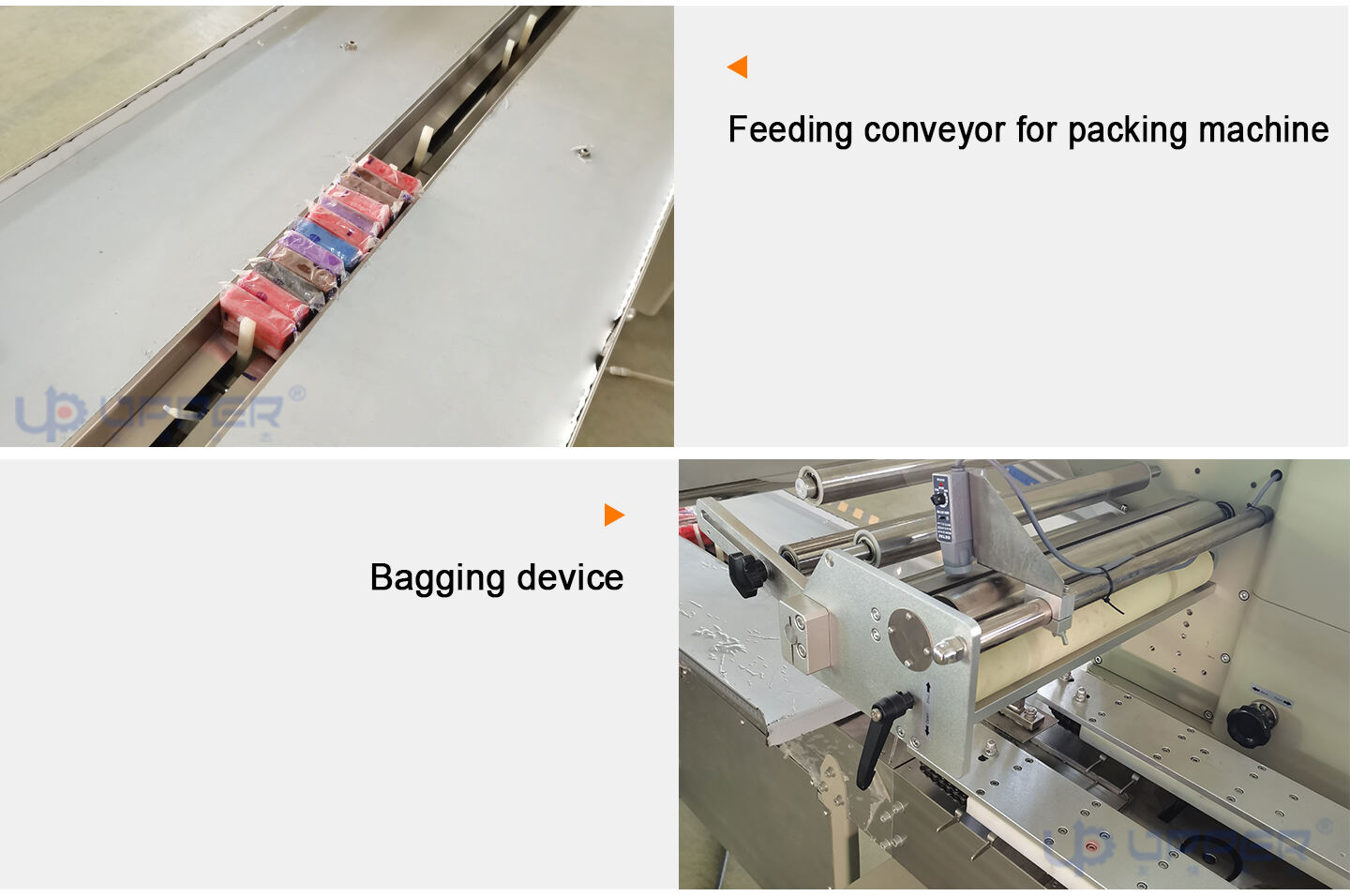

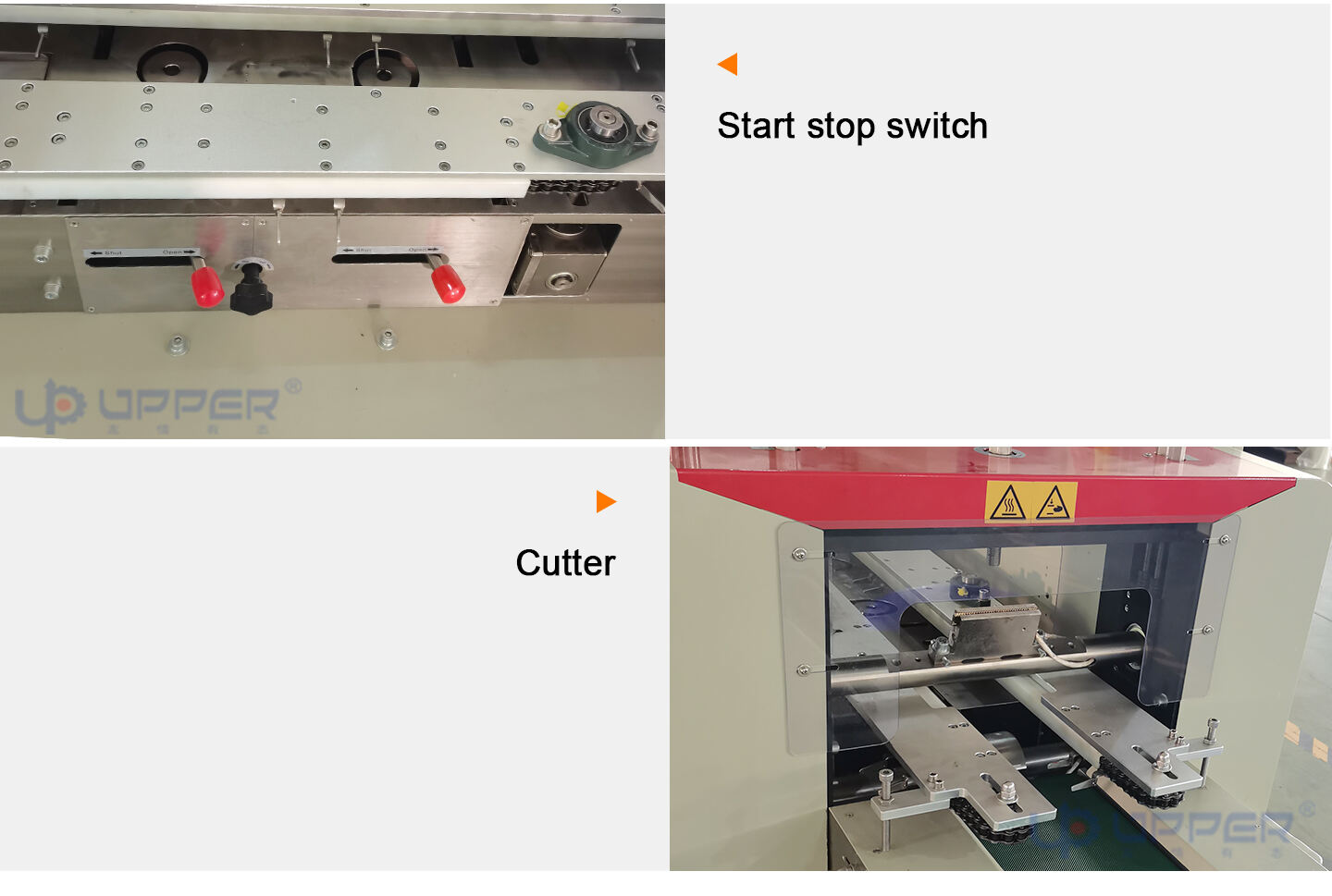

This is a play dough Automtic feeding and packaging line.This production line combines advanced mechanical technology and automation technology. Materials are placed through the feeding port, sorted through multiple channels, and then arranged by sensors for product spacing. Finally, they are transported to the packaging machine for product packaging. The packaging is cut by a cutter to complete the process. The fully automated processing greatly improves production efficiency, reduces labor costs and intensity.

| Model | UPX-CNSJBZ |

| Product name | Play dough feeding and packaging line |

| Packing capacity | 30-100 bags/min |

| Packing Material | Film |

| Dimension range(L:W*H) | 4500*1500*1000 mm can customize according to your requirement |

| Power supply | 220V / 380V 50HZ |

| Total power | 3.2KW |

| Bag size | 90-450(mm) Depending on the material |

| Net Weight | 1200KG |

Suitable for block materials with high hardness such as colored clay, soap, sugar cubes, etc

Suitable for block materials with high hardness such as colored clay, soap, sugar cubes, etc

The product adopts stainless steel structure, humanized design, simple and quick installationdisassembly and maintenance.Durable, hygienic production environment, long working hours, continuous output of products

The product adopts stainless steel structure, humanized design, simple and quick installationdisassembly and maintenance.Durable, hygienic production environment, long working hours, continuous output of products

Foshan UPPER machinery equipment co.,td is an innovative automated packaging equipment manufacturelintegrating R&D, design, manufacturing, sales and after-sales. Since its establishment more than ten yearsago, the company has attracted a group of more than 80 professionals who are persistently pursuing themechanical industry. The number of talents who have grown up with the company has reached 12, and theyhave designed and manufactured automatic packaging equipment with leading technology in China andoversea.

The company specializes in manufacturing: automatic product flow packaging line, pillow packaging machine.food packaging machine, daily chemical products packaging machine, hardware accessories packacinamachine, pouch dispenser, secondary packaging machine, automatic carton packing filing machine, bagsorting machine, customized counting colection machine, customized processing line packaging equipment

Foshan Upper Machinery Equipment Co., Ltd. has professional technical personnel, engineers, sales andafter-sales service personnel, forming a high-gquality, young and innovative team. Always adhere to the tenet of'scientific and technological innovation, quality first, steady development, sincerity and trustworthiness", andprovide customers with high-quality products and services.

Kindly Reminder:

Please let us know the follow packing details when you offer,so that we can check if this model is suitable for your case.

1. Product details

2. Bag width,bag length

3. Bag shape

4. Packing film material

5. Machine frame

Our friendly team would love to hear from you!