Chocolate energy bar counting collection turntable sorting packaging line/Popcorn Stick Fruit Strips Automatic Detection Secondary Packaging Line

Product Description

Product Description

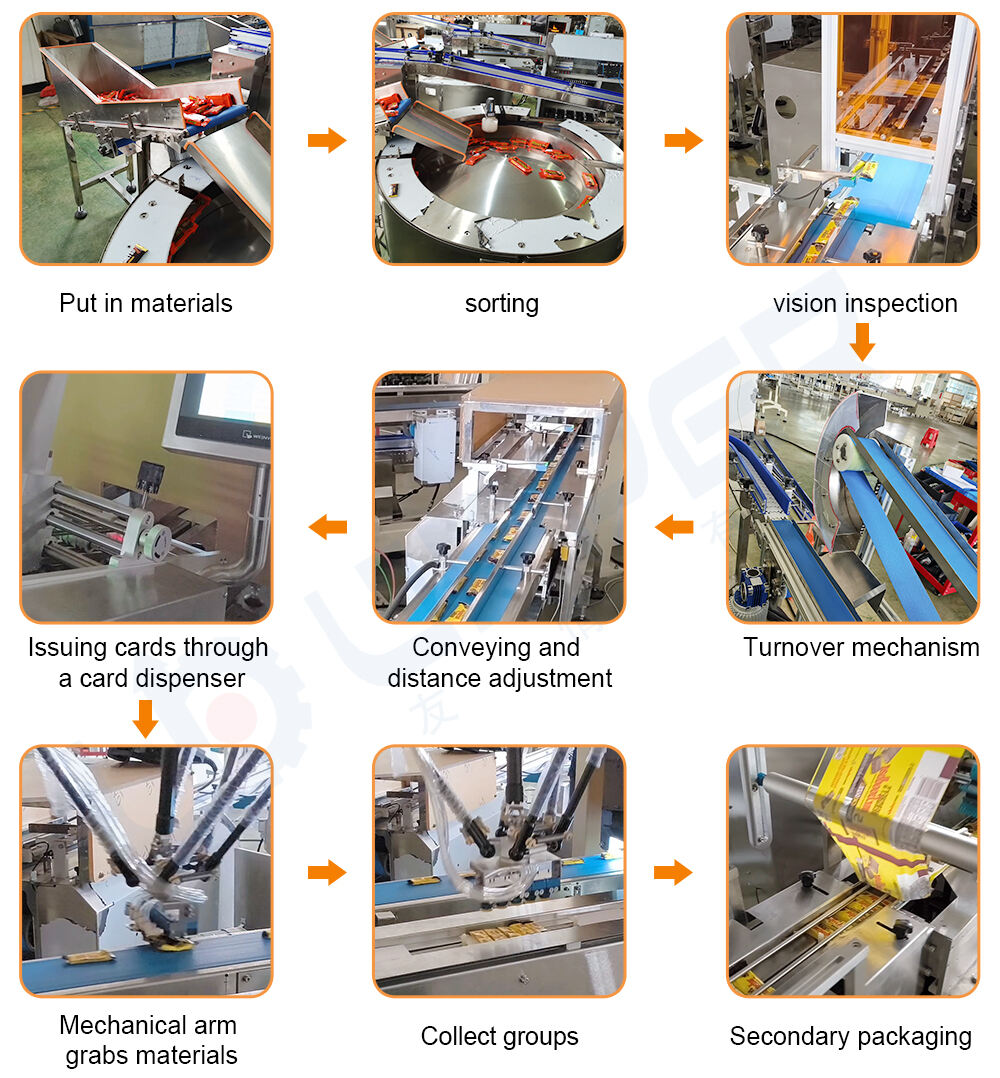

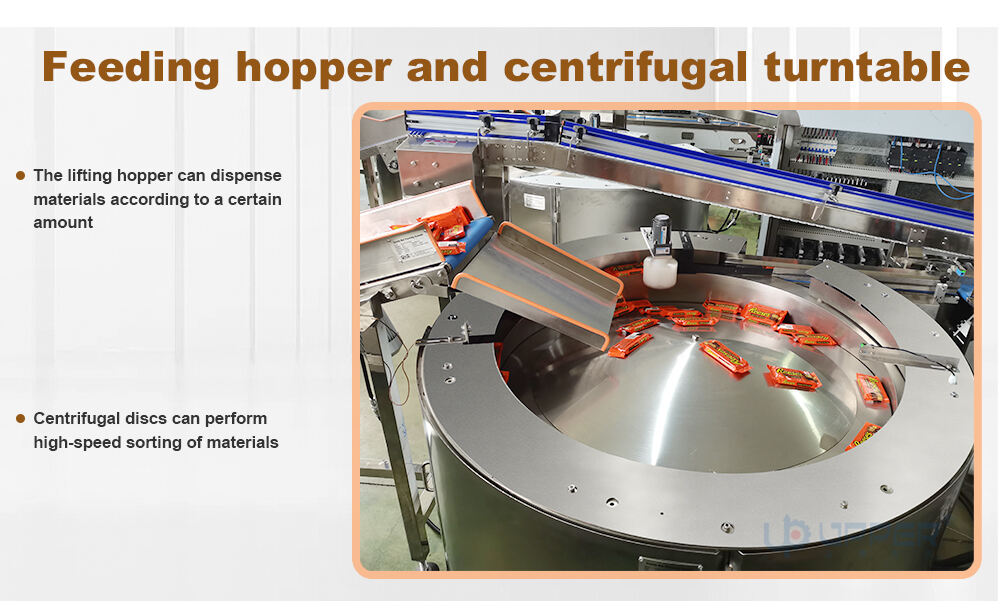

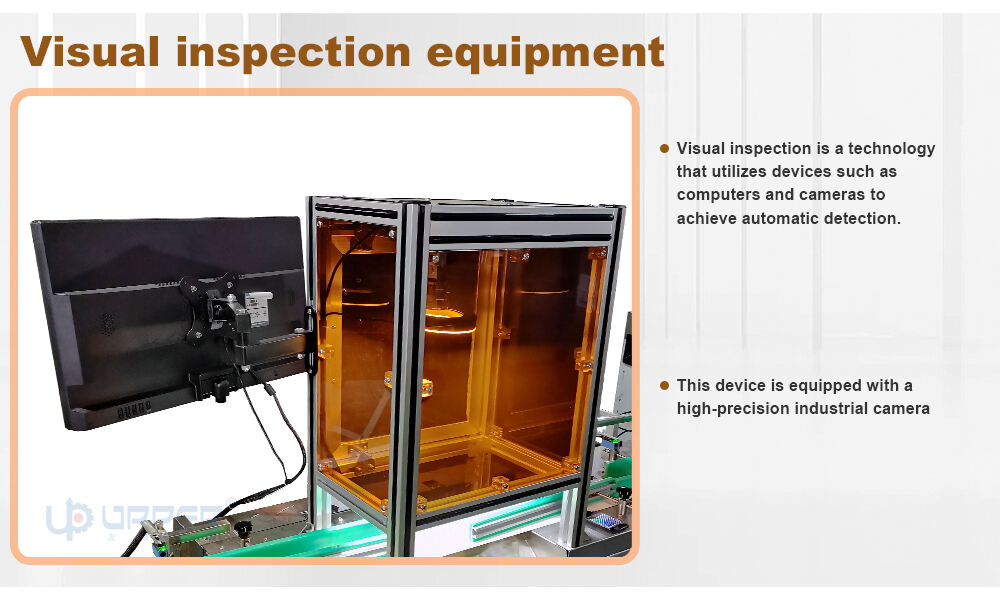

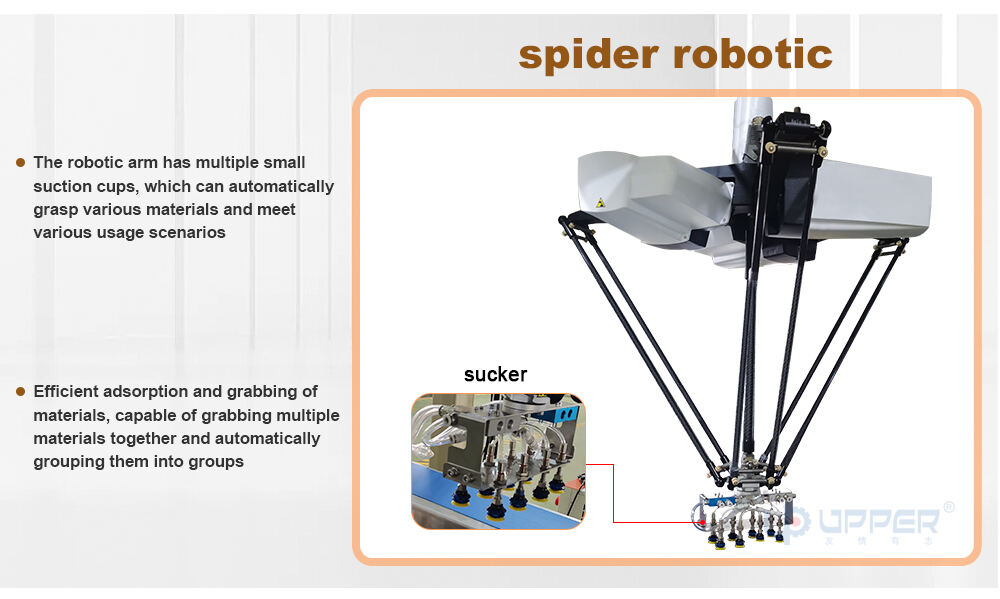

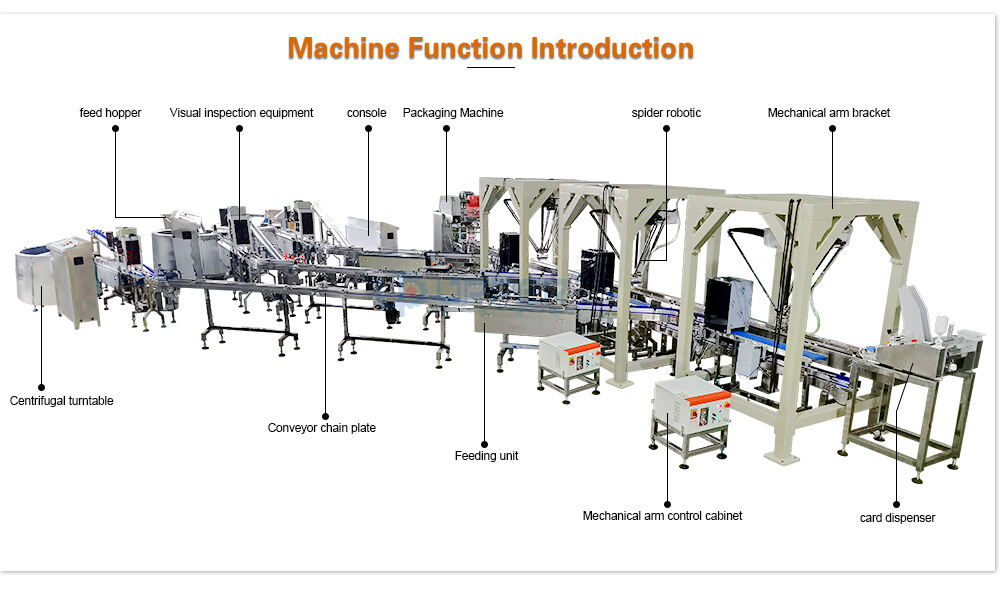

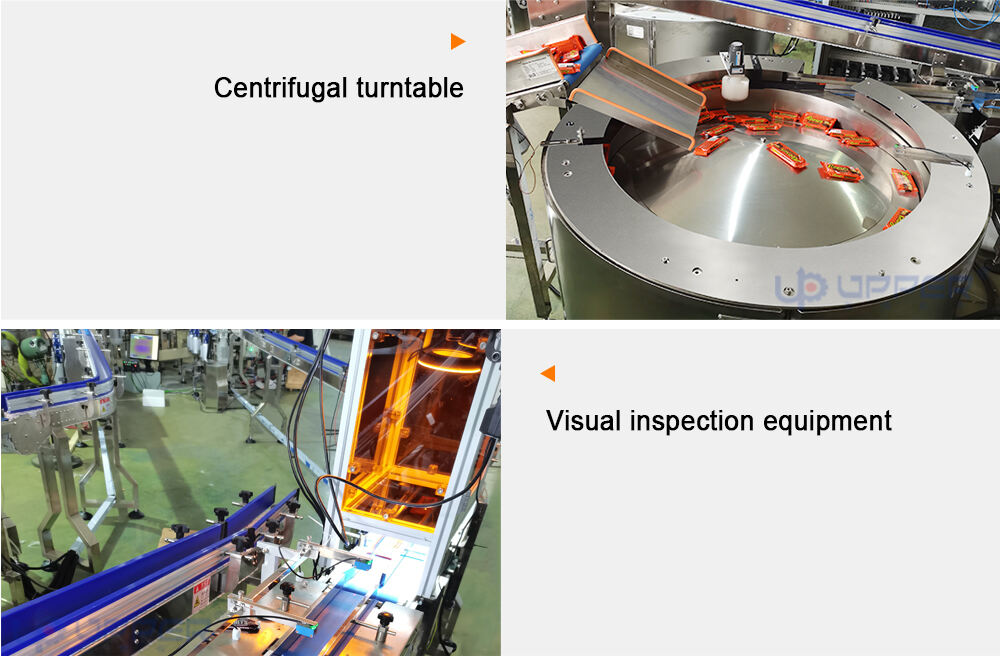

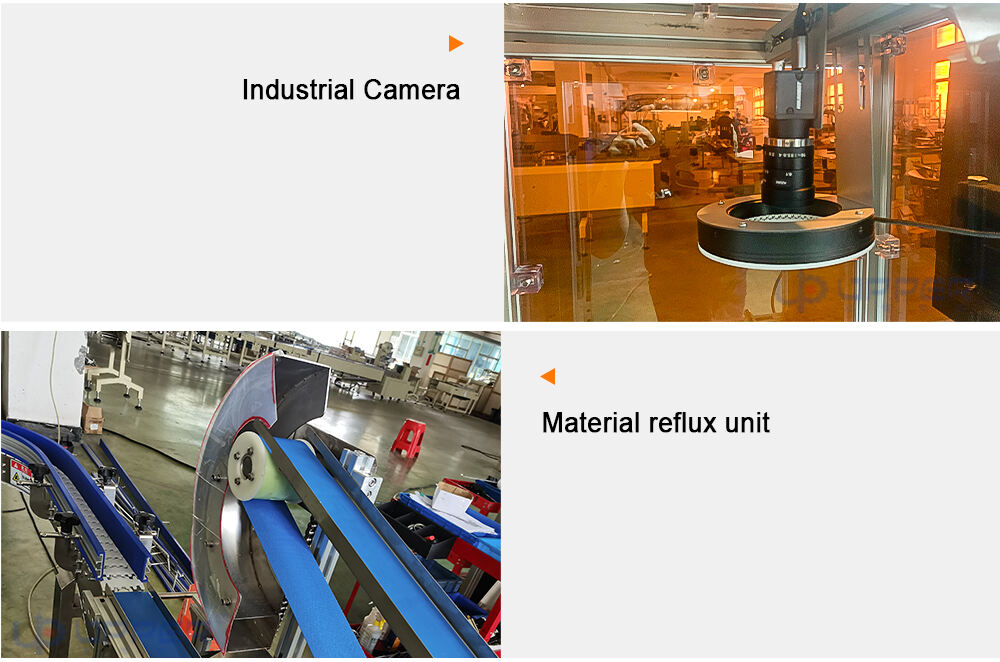

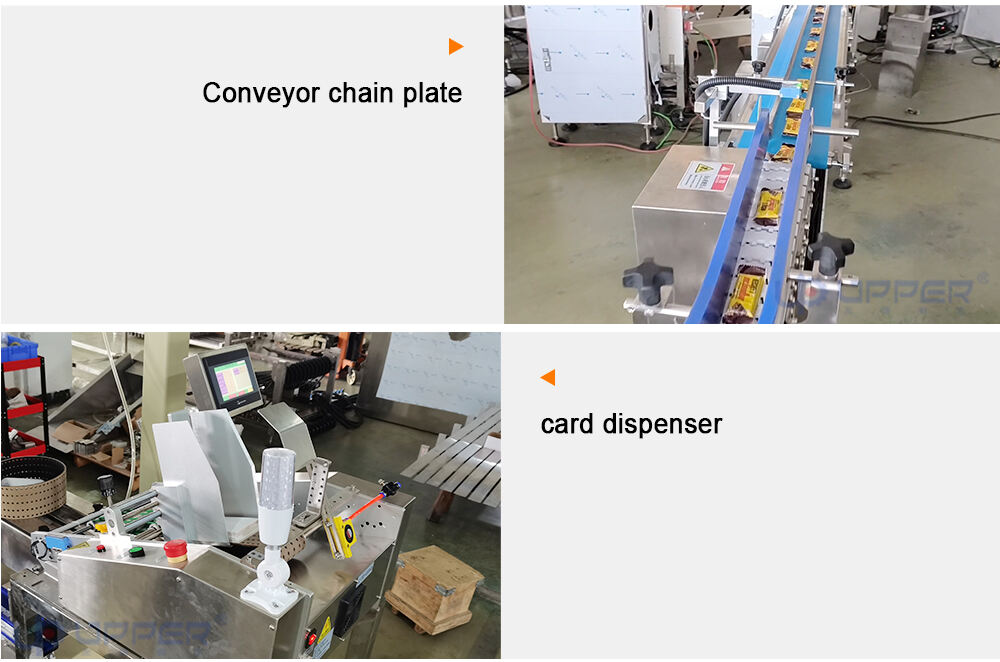

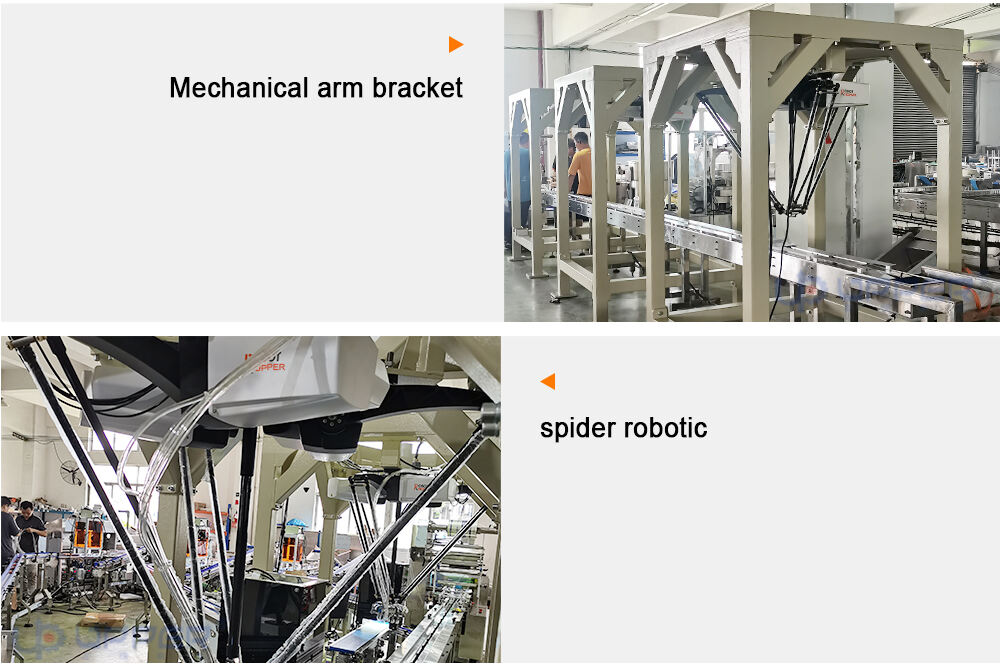

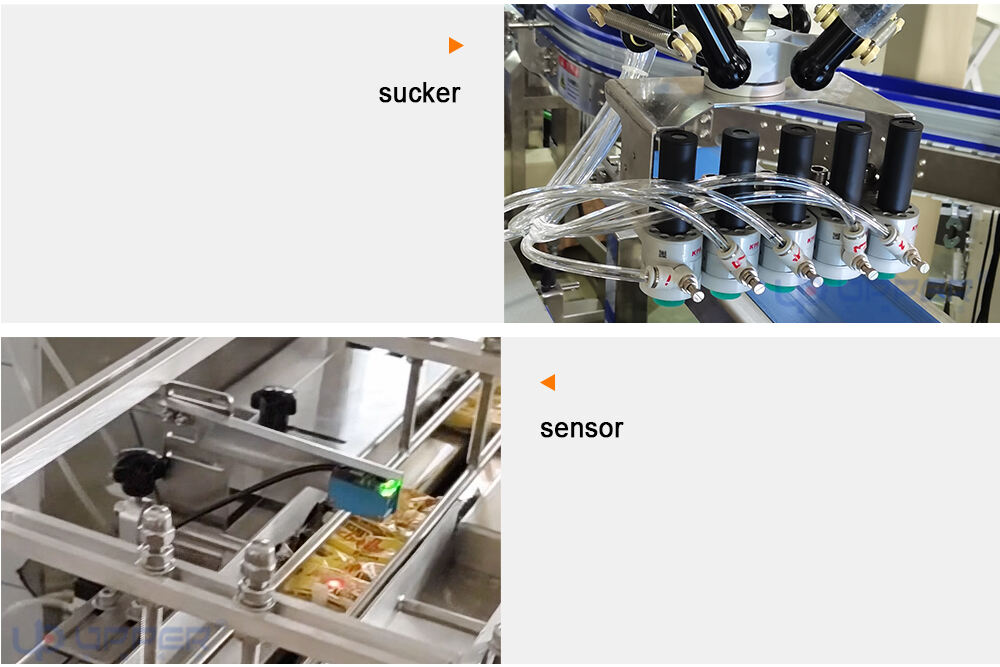

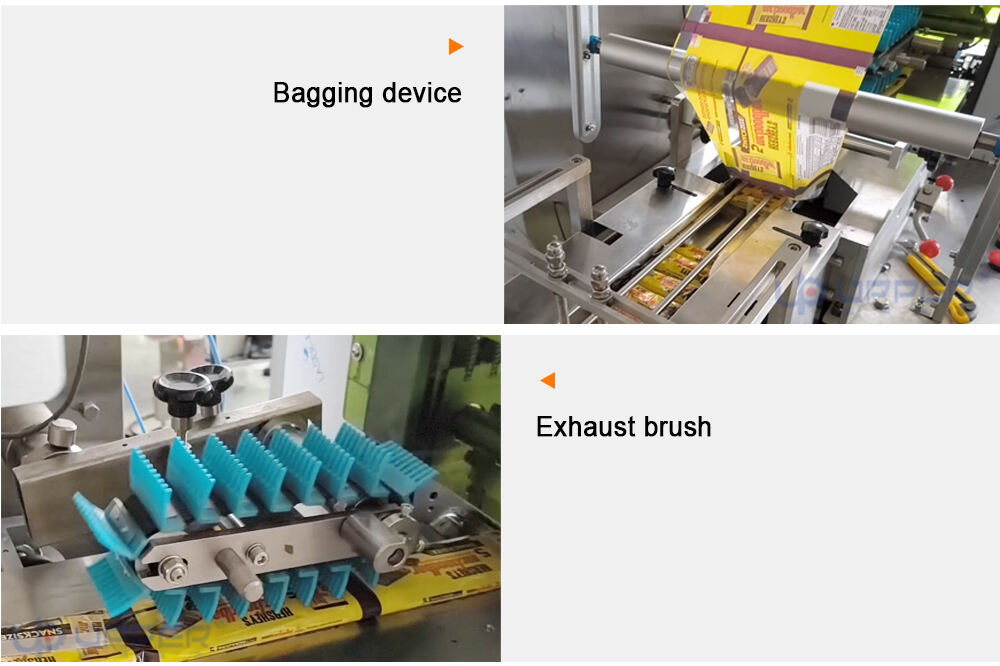

This automated packaging system integrates three centrifugal turntables, three spider robot arms, and a vision inspection module, designed for high-speed sorting, handling, and packaging of materials in food, beverage, and tea powder industries.Key Features High-Speed Centrifugal Sorting Three centrifugal turntables utilize centrifugal force to evenly distribute and align materials (e.g., chocolates, coffee powder, fruit strips), boosting throughput by 30% vs. conventional methods.AI-Powered Vision Inspection High-precision cameras and AI algorithms detect defects (color, shape, surface flaws) with ≥99.5% accuracy, ensuring only qualified products proceed.Intelligent Robotic Handling Three 6-axis spider robots grasp materials with ±0.1mm precision, group them into preset quantities, and transfer to packaging units seamlessly.End-to-End Automation Fully automated workflow from sorting to packaging (60-120 packs/min), minimizing manual operation and contamination risks.Multi-Material Adaptability Modular design supports diverse formats (granules, powders, strips), enabling quick changeovers for flexible production.Competitive Advantages 30% Higher Efficiency: Centrifugal sorting + robotic coordination outperforms traditional vibratory feeders.Zero Human Contact: Compliant with GMP/HACCP standards for food safety.Ultra-Low Waste: Vision-guided precision reduces material loss to <0.3%.Scalable Integration: Compatible with vertical/pillow pouch sealers, canning lines, and existing factory setups.Applications Ideal for chocolate/candy manufacturers, coffee/tea powder processors, health food producers (fruit bars, nut packs), and other scenarios requiring high-speed, hygienic packaging.

| Model | UPX-3TBRot |

| Product name | Chocolate turntable sorting packaging line |

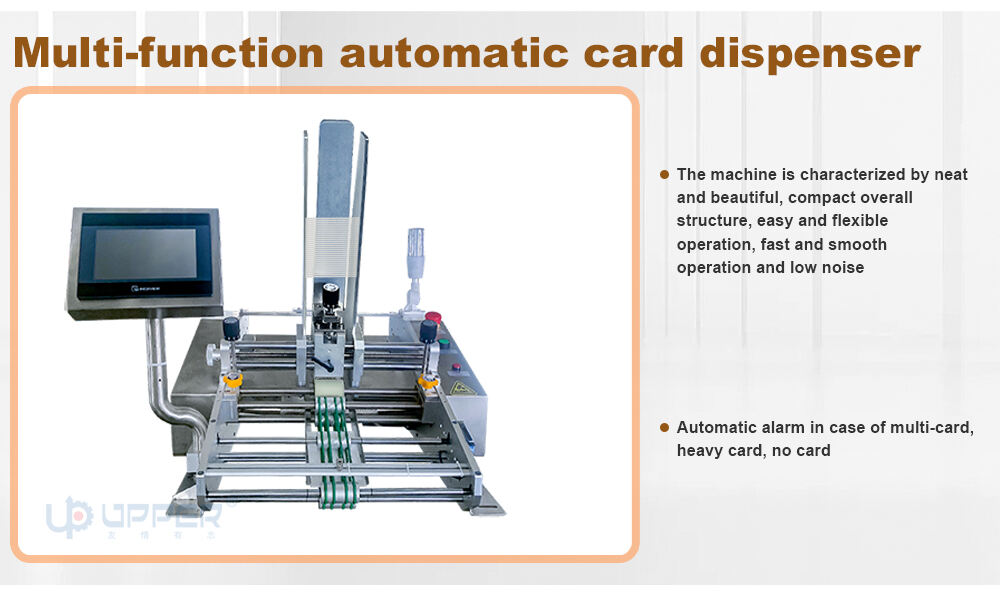

| Accessory | Visual inspection equipment, card dispenser, spider manipulator |

| Sorting speed | 50-120 pieces/mins |

| Applicable materials | Materials such as strips, blocks, circles, squares, etc |

| Function | Collect, organize, test, classify, screen, and package |

| Automaticity | Fully automatic |

| Voltage | 220V /380V 50Hz |

| Weight (KG) | According to the actual situation |

| power | 3.2 KW |

| Dimension range(L:W*H) | According to the actual situation |

| Return angle of robotic arm to zero | 1 axis: -35.585/2 axis: -35.585 /3 axis: -35.414 |

Suitable for various independent packaging of secondary packaging, such as chocolate, cookies, coffee powder, etc.

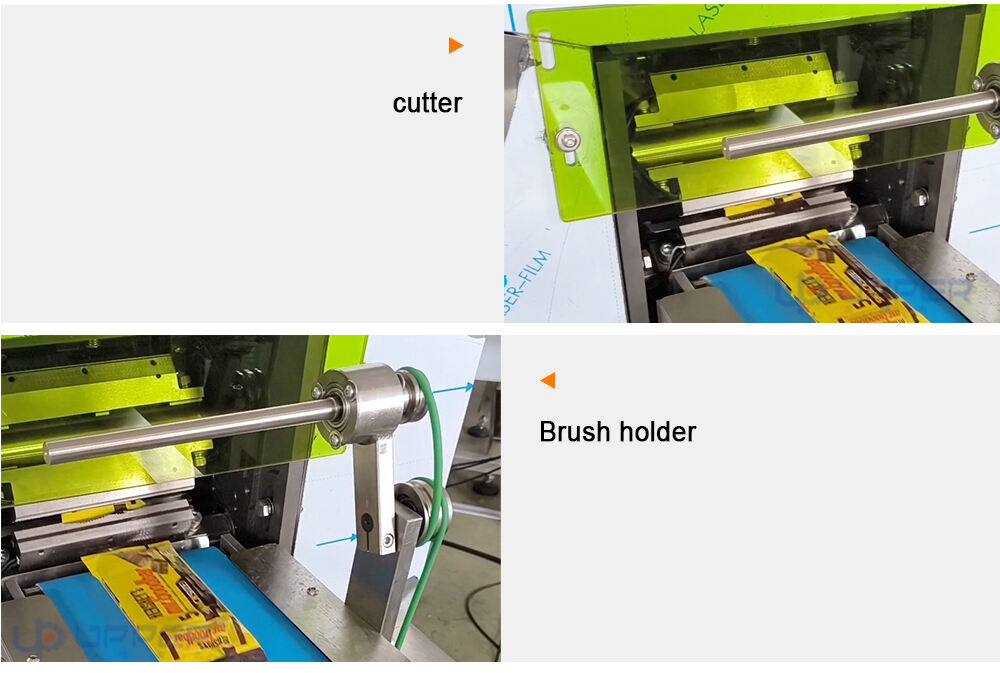

The product adopts stainless steel structure, humanized design, simple and quick installationdisassembly and maintenance.Durable, hygienic production environment, long working hours, continuous output of products

The product adopts stainless steel structure, humanized design, simple and quick installationdisassembly and maintenance.Durable, hygienic production environment, long working hours, continuous output of products

Foshan UPPER machinery equipment co.,td is an innovative automated packaging equipment manufacturelintegrating R&D, design, manufacturing, sales and after-sales. Since its establishment more than ten yearsago, the company has attracted a group of more than 80 professionals who are persistently pursuing themechanical industry. The number of talents who have grown up with the company has reached 12, and theyhave designed and manufactured automatic packaging equipment with leading technology in China andoversea.

The company specializes in manufacturing: automatic product flow packaging line, pillow packaging machine.food packaging machine, daily chemical products packaging machine, hardware accessories packacinamachine, pouch dispenser, secondary packaging machine, automatic carton packing filing machine, bagsorting machine, customized counting colection machine, customized processing line packaging equipment

Foshan Upper Machinery Equipment Co., Ltd. has professional technical personnel, engineers, sales andafter-sales service personnel, forming a high-gquality, young and innovative team. Always adhere to the tenet of'scientific and technological innovation, quality first, steady development, sincerity and trustworthiness", andprovide customers with high-quality products and services.

Kindly Reminder:

Please let us know the follow packing details when you offer,so that we can check if this model is suitable for your case.

1. Product details

2. Bag width,bag length

3. Bag shape

4. Packing film material

5. Machine frame

Our friendly team would love to hear from you!